Business Areas

T.S. Renewable Energy supply state-of-the-art equipment for all our biomass projects. Through continuous technological and management innovation, we offer better environmental solutions by adopting appropriate combustion systems to suit different fuels. An effort all directed towards supporting sustainable energy that empowers responsible end users.

PHASE 1

Initial Development

Tap on Our Expertise

Our experienced team of consultants will evaluate your site and surrounding environment to assess the feasibility of establishing a power plant, and calculate your projected investment, power generation potential and rate of returns.

A customised plant that works for you

If establishing a plant is feasible, our consultants will sit down with you to discuss the limitations and possibilities, and to understand your goals before presenting you with a preliminary design based on your budget and desired lifespan of your plant.

- Technological & Economic Feasibility Studies

- Environmental Assessment

- Identification of Client’s Needs

- Conceptual Design & Proposal of Power Plants

- Preliminary Agreement Negotiation

PHASE 2

Detailed Development

Planning for a smooth delivery

Our goal is to get your plant up and running by or before the agreed timeline. Our project management team will work with you to oversee the finalisation of legal agreements and support in the approval of necessary permits, while our design and engineering teams get to work on finalising the detailed design and specifications of your plant.

No compromise on safety

Our designers and engineers will focus on achieving the fast assembly of the plant on site to the required specifications. Throughout this planning process, the safe operation of your plant is our top priority.

- Finalisation of Agreement

- Planning of Ownership & Financing Structure

- Application for Permits & Approvals

- Engineering & Design Consultation

- Detailed Planning & Design of Plant

PHASE 3

Procurement & Delivery

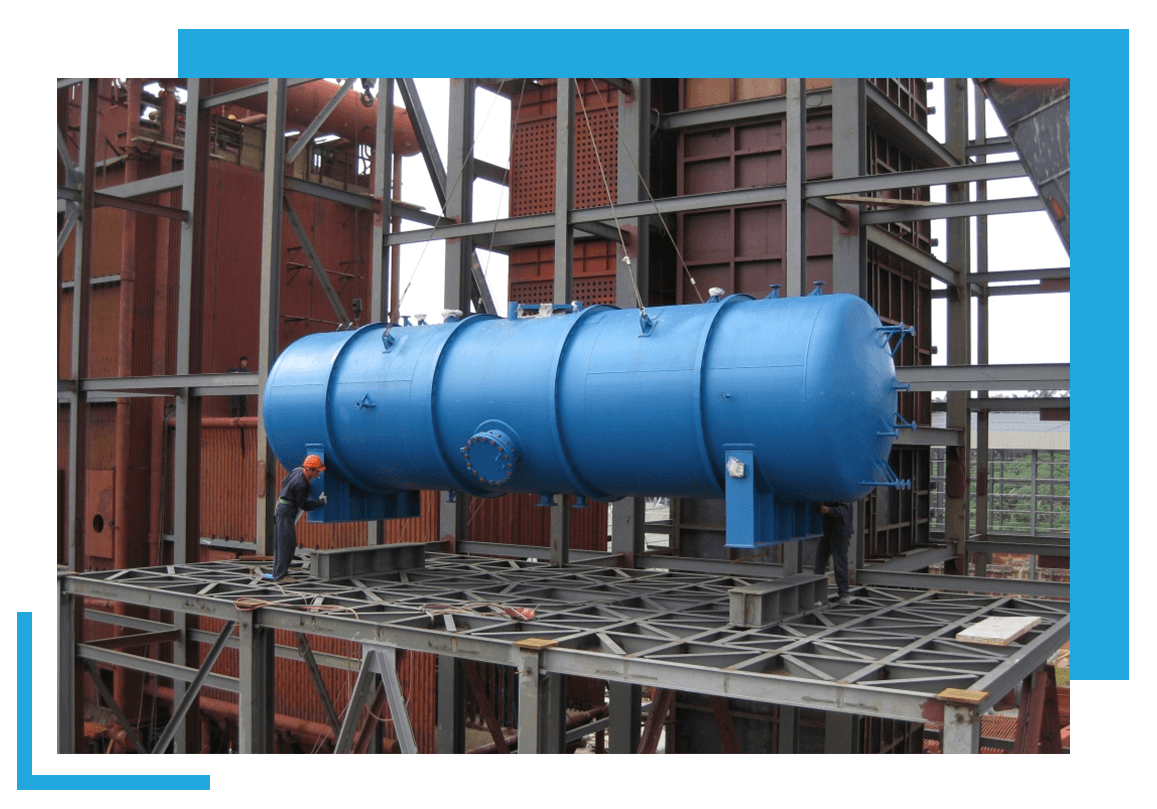

Procurement from trusted suppliers

Our stringent procurement processes involve sourcing the ideal equipment for your needs and budget to ensure you get the most value for your investment.

Factory Acceptance Test (FAT)

We will conduct Factory Acceptance Test (FAT) for major equipment before shipment.

- Procurement & Fabrication of Power Plant Equipment

- Shop Testing & Inspection

- Shipment / Delivery to Project Site

PHASE 4

Project Execution

Attention to every detail

Upon delivery of each piece of equipment to your site, we will inspect before installation to ensure the required safety and quality standards are met.

Bringing it all together

We assemble the plant and perform a full system integration before testing and commissioning takes place.

Once installations are completed, we perform all the necessary checks, which includes no-load test and full load test before the actual plant performance test and finally handing over the plant to the end-user.

- Turnkey Erection & Installation of Power Plant

- Full System Integration

- Testing & Commissioning

- Performance & Reliability Test

PHASE 5

Plant Operation

Full Training Provided

Orientation and maintenance training for your engineering and operational staff. This includes control room operations, maintenance and management to help you operate your plant at full efficiency and ultimately prolong its lifespan.

Support Packages Customized To Your Requirements

Post-integration, we will design a comprehensive customized support package aimed to keep your plant in operation and minimize downtime. We can either support you in a technical advisory role or provide full power plant management services.

- Training for Operators

- Commencement of Operations O&M Management

- Spare Parts Supply & Maintenance

- Management

- Technical Advisory Support

- Power Plant Management